ATLAS Gyratory Sifter

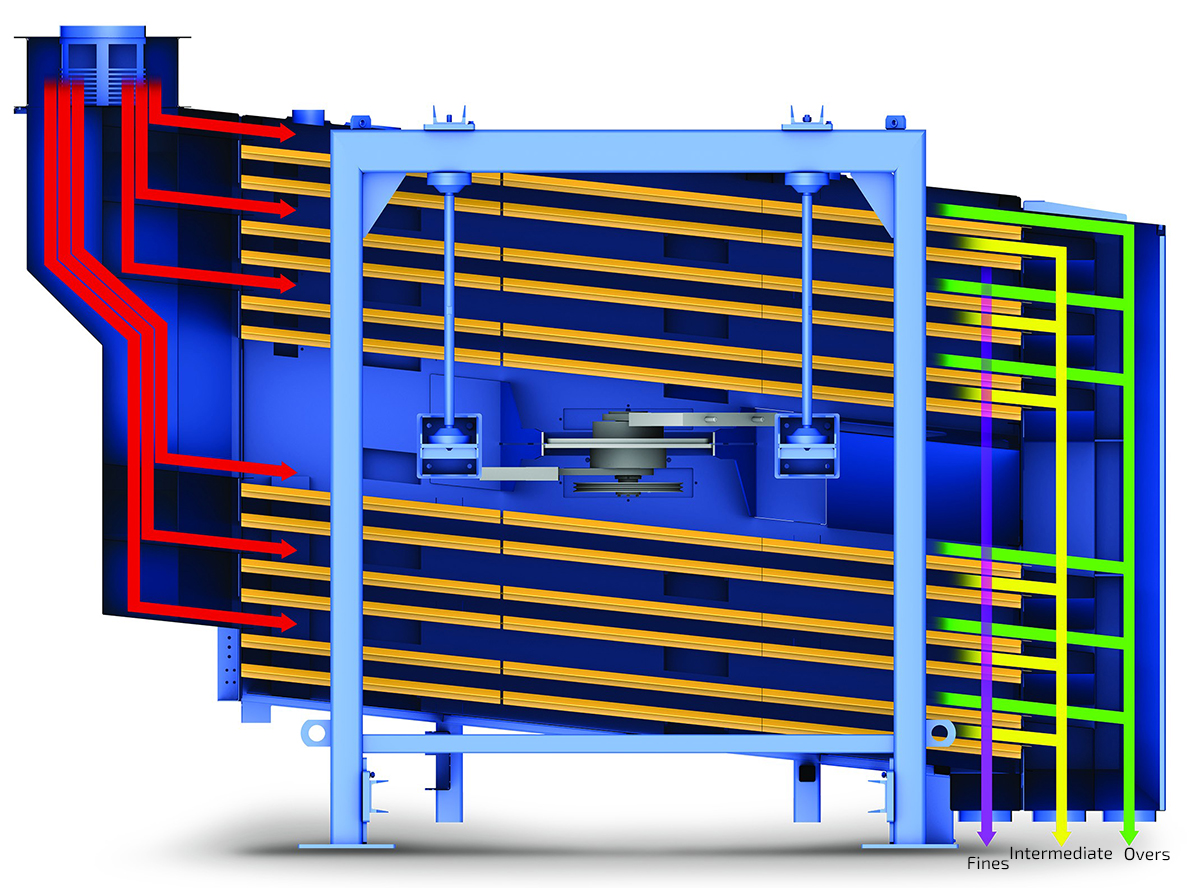

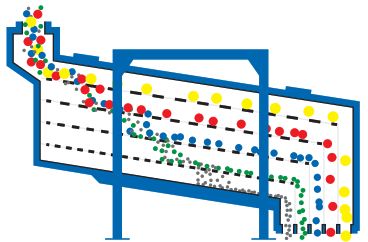

The SWECO ATLAS Gyratory Sifter is our biggest sifter yet, offering high capacity screening in a low maintenance, operator-friendly design. The horizontal, uniform gyratory motion of the ATLAS provides the highest performance per screen area available on the market, which means sharper separations, higher volume, exceptional screen cleaning, low dynamic force and unparalleled material spread-ability.

The SWECO ATLAS Gyratory Sifter is our biggest sifter yet, offering high capacity screening in a low maintenance, operator-friendly design. The horizontal, uniform gyratory motion of the ATLAS provides the highest performance per screen area available on the market, which means sharper separations, higher volume, exceptional screen cleaning, low dynamic force and unparalleled material spread-ability.

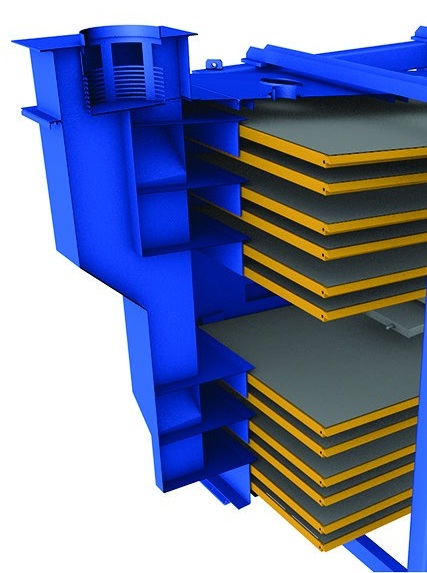

More Screening Area

Ideal for a wide range of industries including chemical, food, plastics, agriculture and minerals, the ATLAS Gyratory Sifter is available in 33 versatile configurations with up to 12 screens, ranging from 32ft² (3m²) to 528ft² (49m²) of screening area, and 2-5 product fractions.

Engineered for Maximum Uptime and Ease of Use

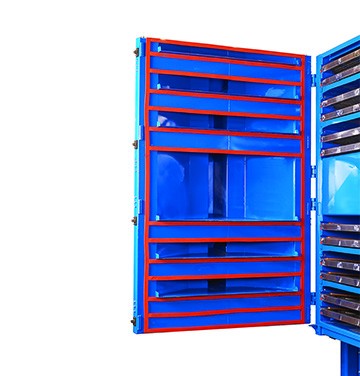

Engineered for maximum uptime and ease of use, the drive and basket hangers of each ATLAS configuration are maintenance free, with no lubrication required. Additionally, each ATLAS model integrates SWECO’s patented QuickChange™ technology, allowing for one minute screen changes, which can be performed from either the feed or the discharge end of the machine. These features significantly reduce equipment downtime, leading to greater production capacity. Additional benefits include a high-performance feed box, discharge door and superior deblinding ball action.

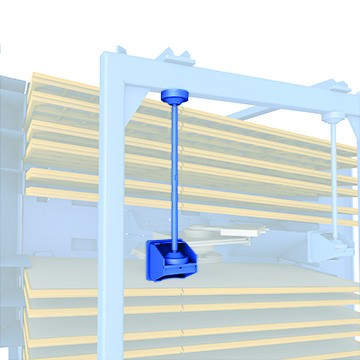

Dynamic hanger system*

• Maintenance free

• Pre-balanced design

• Unparalleled repeatability

• 3-year warranty

High-performance feed box*

• Flexible configuration

• High-wear design

• Quick field replacement

• Material is evenly distributed to each screen level

• Material is spread prior to contact with screen

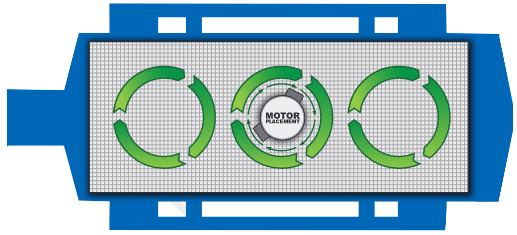

Adjustable Split Drive*

Adjustable Split Drive*

• Symmetrical weight assembly

• One minute belt change

• Optional high-temp design 400°f/204°c

• Lubricated for life

• 3-year warranty

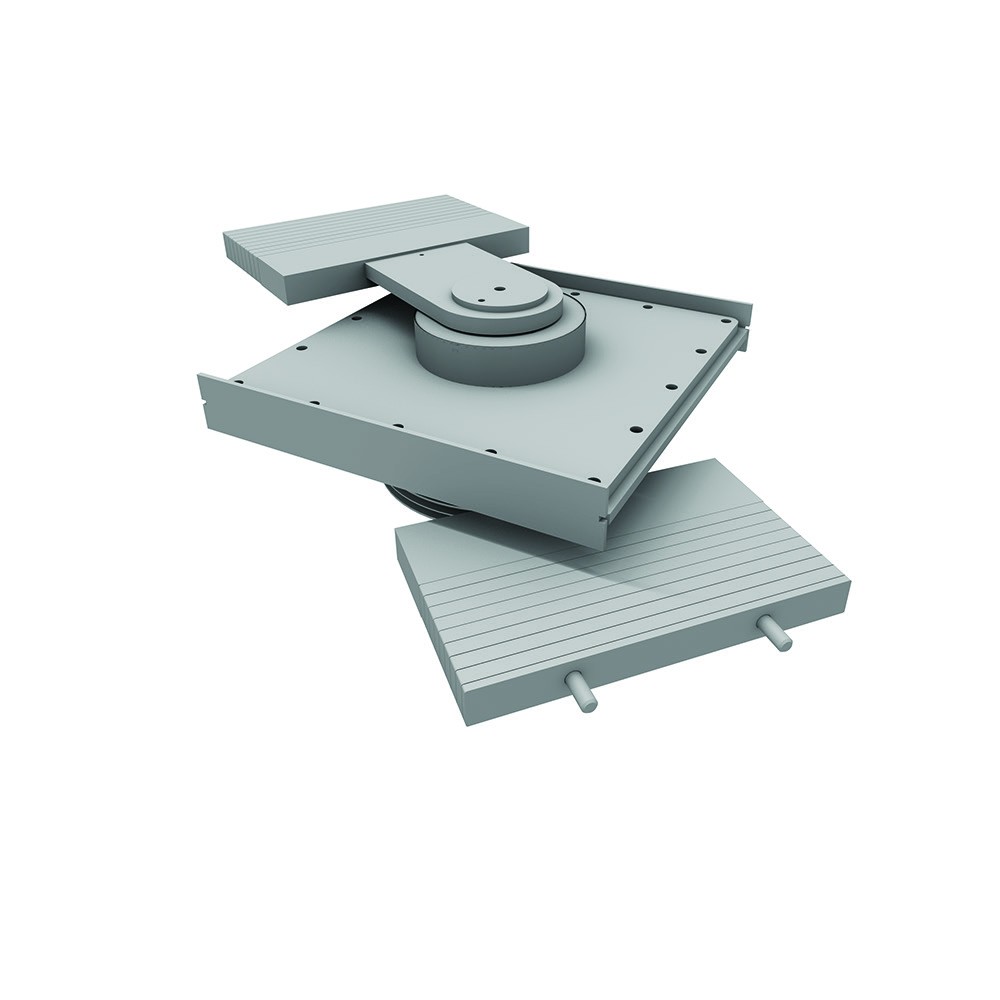

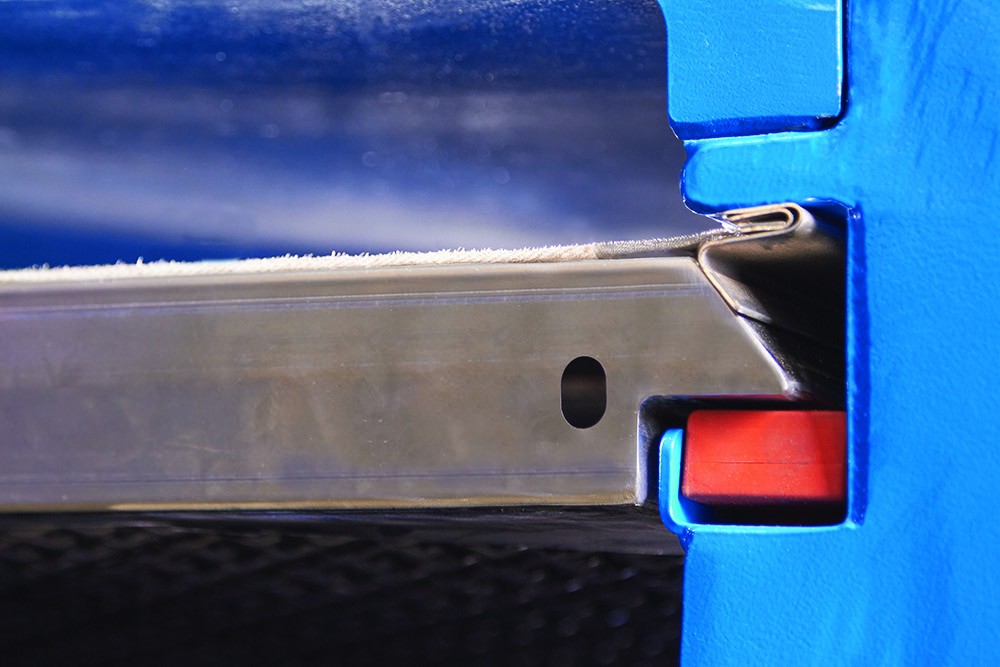

Pneumatic QuickChange™ screen technology*

Pneumatic QuickChange™ screen technology*

• One minute screen change

• Auto-tension adds increased efficiency /screen life

• Screen replaced from either end

• Ergonomic design, no need to remove ball boxes

Discharge door

Discharge door

• Screen extension design increases efficiency

• Waterfall flow enhances product discharge

• Centerline outlets

• Footprint reduction

*Features Patent Pending worldwide

SWECO’s horizontal uniform gyratory motion offers the highest performance per screen area

SWECO’s horizontal uniform gyratory motion offers the highest performance per screen area

Sharp separations | High capacity | Superior screen cleaning | Low dynamic force | Material spread-ability

SWECO ENGINEERED CUSTOMER APPROVED

5.5 ft x 12 ft screen dimension

5.5 ft x 12 ft screen dimension

• Single screen prevents product bypass

• Increased retention time

• Better exposure to nearsize particles

• More efficient separations

Superior deblinding ball action

• More frequent ball impacts

• Feed, center & discharge end

Gyratory Sifter Portfolio

[ft2 ] /[m2 ]

QUICKCHANGE™

SCREEN TECHNOLOGY

FRACTIONS

MOTION

[hp] / [kW]

3 - 49 m2

√

3.7 - 7.5 kW

3 - 36.8 m2

3.7 - 7.5 kW

4.5 - 24.5 m

3.7 - 7.5 kW

4.5 - 12.3 m2

3.7 - 7.5 kW