Low Profile Flow-Thru Separators

1. The SWECO LX Low Profile Flow-Thru Separator

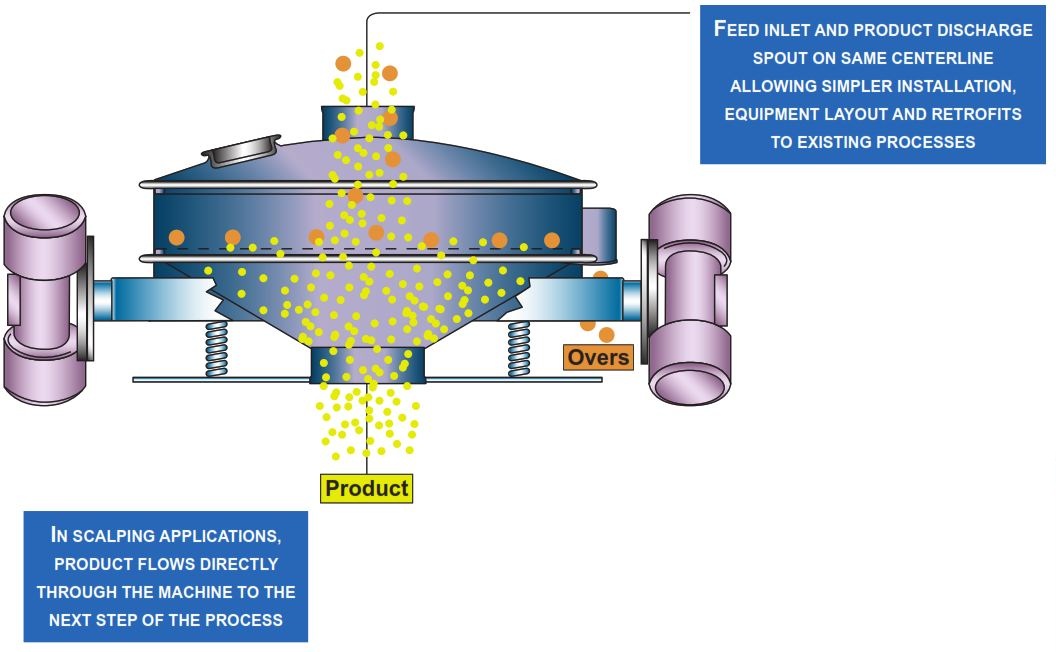

The SWECO LX Low Profile Flow-Thru Separator allows for high capacity wet or dry scalping in a compact, low headroom design. Dual motors mounted on opposite sides of the LX allow unrestricted flow of material and create the 3-D motion that allows oversize material full discharge, keeping the screen clear for maximum product flow. Its low headroom requirements (as little as 15 inches) and straight flow design, allow the LX to fit easily into existing product lines without reworking the entire system.

Sweco® Low Profile Flow-Thru Separator offers high capacity wet or dry scalping in a compact, low headroom design. Dual motors mounted on opposite sides of the Low Profile create the 3-D motion that allows maximum flow-thru of material. Because of its low headroom requirements (as little as 15 inches) and straight, flow-thru design, the Low Profile fits easily into existing product lines without reworking the entire system. Inlets and outlets can be custom designed to mate with existing equipment and piping. The Low Profile is ideally suited for prepackaging screening in many food and pharmaceutical applications, as well as for bulk bag unloading and screening of raw ingredients.

THE LOW HEADROOM REQUIREMENT ALLOWS INSTALLATION IN EXISTING PROCESSES

High Capacity. Minimal Headroom. Minimal Headroom.

OPTIONS

» MOBILE STAND MOUNTED ON CASTERS FOR BAG UNLOADING

» SINGLE MOUNT MOTOR DESIGN ALSO AVAILABLE DISCHARGE MAGNET TO AID IN CAPTURE OF METAL CONTAMINANTS CAN BE USED IN CONJUNCTION WITH MAGNETIC SCREENS

APPLICATIONS:

» BAG EMPTYING ABOVE MIXERS

» AGGLOMERATE AND FOREIGN MATTER REMOVAL

» OFF-LINE SCREENING AND PRODUCT RECLAIM

» INGREDIENT SCREENING

» PREPACKAGING SCREENING

Available in 18” thru 72” diameter machines

» Greater Throughput - Dual side mount motors allow for maximum flow-thru of material through the separator. Throughput is determined directly by screen mesh. In addition, oversize material is efficiently removed from the screen surface with 3-D vibratory motion.

» Process Optimization - Separation dynamics and discharge pattern can be optimized by adjusting motor force and motor orientation angle. This allows the user the ability to control the residence time of particles on the screen surface, creating optimal flow characteristics to meet your specific process needs.

» Cost-Effective Retrofits - Due to the low headroom requirement, the Low Profile fits almost anywhere in your existing process without reworking your entire system or even rerouting existing piping.

» Reduced Costs in Hot Material Processes - External mount motors operate at cooler temperatures. In hot applications, there is no need for the forced air cooling required by the internally mounted motors of standard separators.

» Sanitary Design - Internal ground welds, #4 finish and other options are available for sanitary applications to prevent product build-up and contamination.

» Low Profile Accepts Standard Accessories - Ball trays or sliders can be used to reduce screen blinding. Most motor, cover and spout connector options are available. The full line of Sweco screens, including Fusion™ and Magnum™, are available for use in the Low Profile.

2. LA Low Profile Flow-Thru Separator

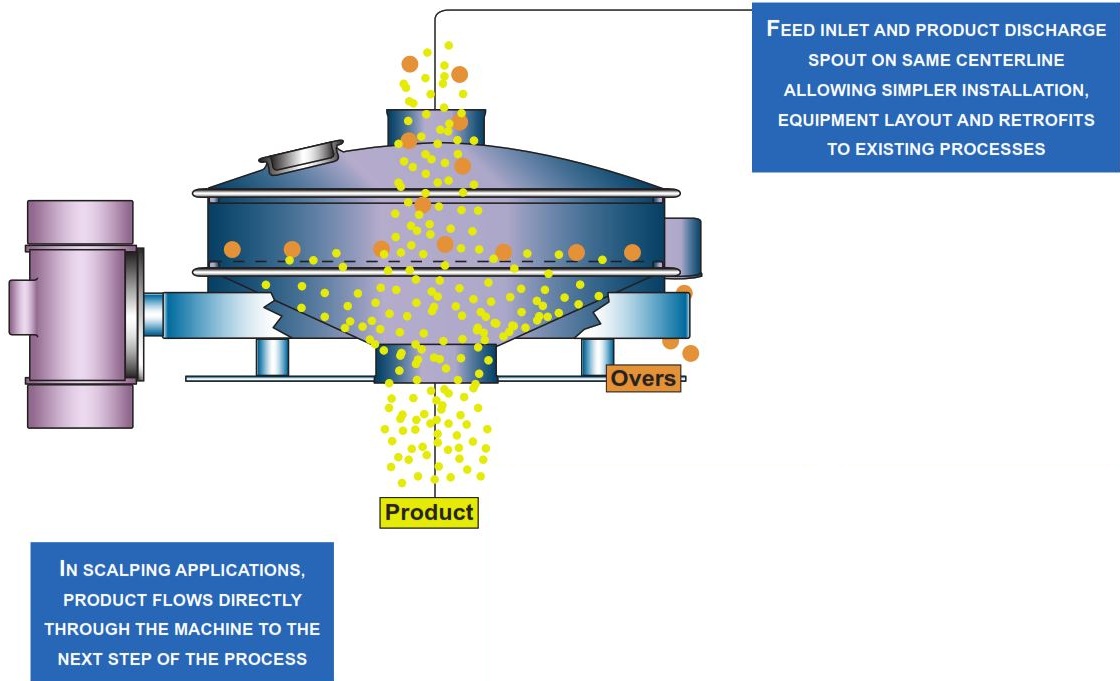

The SWECO LA Low Profile Flow-Thru Separator offers the same high capacity wet or dry scalping in a compact, low headroom design. The LA Separator incorporates asingle large vertically mounted motor to induce a sifting motion across the screen plane. The frames of the separator are mounted on "rubber isolators" compared to "springs" in conventional low profile and other standard separators. Additionally, the LA Separator runs at higher G loadings and speeds than traditional low profile separators.

The SWECO LA Low Profile Flow-Thru Separator offers the same high capacity wet or dry scalping in a compact, low headroom design. The LA Separator incorporates asingle large vertically mounted motor to induce a sifting motion across the screen plane. The frames of the separator are mounted on "rubber isolators" compared to "springs" in conventional low profile and other standard separators. Additionally, the LA Separator runs at higher G loadings and speeds than traditional low profile separators.The SWECO® LA Low Profile Flow-Thru Separator offers high capacity wet or dry scalping in a compact, low headroom design. The LA Separator incorporates a single large vertically mounted motor to induce a sifting motion across the screen plane. The frames of the separator are mounted on ‘rubber isolators’ compared to ‘springs’ in conventional low profile and other standard separators.

Additionally, the LA Separator runs at higher G loadings and speeds than traditional low profile separators. Because of its low headroom requirements (as little as 15 inches) and straight, flow-thru design, the Low Profile fits easily into existing product lines without reworking the entire system. Inlets and outlets can be custom designed to mate with existing equipment and piping. The Low Profile is ideally suited for prepackaging screening in many food and pharmaceutical applications, as well as for bulk bag unloading and screening of raw ingredients.

THE LOW HEADROOM REQUIREMENT ALLOWS

INSTALLATION IN EXISTING PROCESSES

Significantly High Rates. Single Motor Design.

OPTIONS

» MOBILE STAND MOUNTED ON CASTERS FOR BAG UNLOADING

» DUAL MOUNT MOTOR DESIGN ALSO AVAILABLE

» DISCHARGE MAGNET TO AID IN CAPTURE OF METAL ONTAMINANTS CAN BE USED IN ONJUNCTION WITH MAGNETIC SCREENS

APPLICATIONS:

» BAG EMPTYING ABOVE MIXERS

» AGGLOMERATE AND FOREIGN MATTER REMOVAL

» OFF-LINE SCREENING AND PRODUCT RECLAIM

» INGREDIENT SCREENING

» PREPACKAGING SCREENING

Available in 18” thru 40” diameter machines

» Proven Motion - Excellent at sifting lighter products such as flours and starches, the LA motion has been proven to provide higher rates than that of other conventional low profile separators.» Process Optimization - The LA Separator’s pure horizontal, high G motion increases the capacity of the undersize product passing through the screen while allowing the oversize material to exit the separator.

» Cost-Effective Retrofits - Due to the low headroom requirement, the LA Low Profile fits almost anywhere in your existing process without reworking your entire system or even rerouting existing piping.

» Reduced Costs in Hot Material Processes - The external mount motor operates at a cooler temperature. In hot applications, there is no need for the forced air cooling required by the internally mounted motors of standard separators.

» Sanitary Design - Internal ground welds, #4 finish and other options are available for sanitary applications to prevent product build-up and contamination.

» LA Low Profile Accepts Standard Accessories - Ball trays or sliders can be used to reduce screen blinding. Most motor, cover and spout connector options are available. The full line of SWECO screens, including Fusion™ and Magnum™, are available for use in the LA Low Profile.